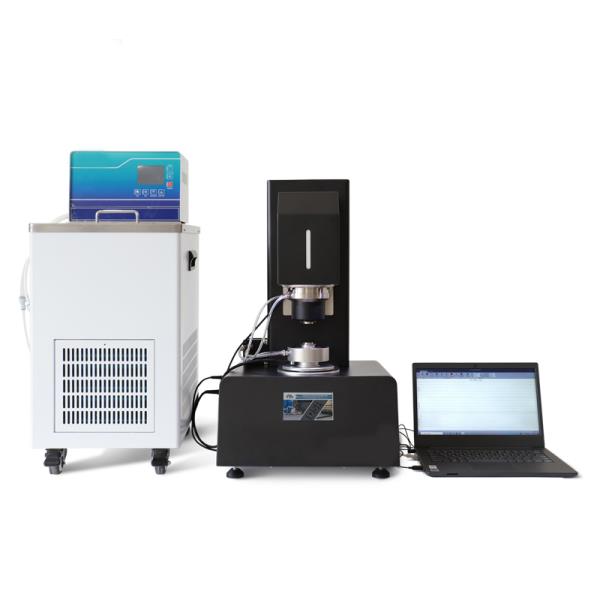

Dynamic Shear Rheometer (DSR)

The dynamic shear rheometer (DSR) is used to evaluate the viscous (non-recoverable) and elastic (recoverable) properties of aged and unaged asphalt in the temperature range 5-85 ºC by measuring the dynamic shear modulus G* and phase angle s of the bitumen to predict the ability to resist rutting and fatigue cracking.

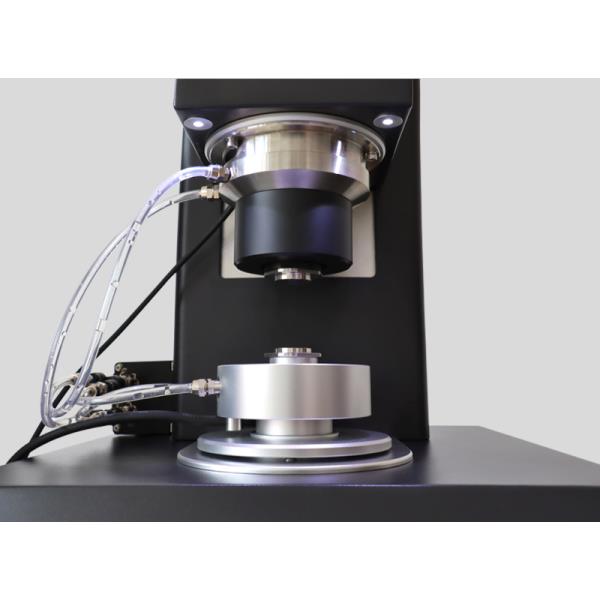

The DSR test uses a thin asphalt binder sample sandwiched between two circular plates. The lower plate is fixed while the upper plate oscillates back and forth across the sample to create a shearing action.

Ultra-low inertia servo motor technology.

The DSR test uses a thin asphalt binder sample sandwiched between two circular plates. The lower plate is fixed while the upper plate oscillates back and forth across the sample to create a shearing action.

Ultra-low inertia servo motor technology.

- Smooth positioning and drive speed regulation are realized through toothless torque.

- Ultra-low inertia hollow cup motor design, fast torque and speed response, and excellent dynamic characteristics.

- Relative to the volume and weight of the motor itself, it can provide extremely high torque and power.

- Absolute linear relationship between current and torque, voltage and speed.

- Optical encoder, with a resolution of 10-4 rad, can accurately measure the rotational angular displacement and angular velocity.

- Ultra-high sensitivity normal force sensor design, fast transient response, accurate measurement and control of normal force.

- Ultra sensitive torque sensor design, which can accurately measure rotor torque.

- The ultra-high precision grating system accurately measures and controls the vertical running position, and the gap resolution is 0.1 μm.

- Peltier temperature control system is adopted, and high-resolution temperature sensor is embedded to ensure fast and accurate sample temperature control.

- One step plug-in design of power supply, communication and fluid connection, fast, convenient and firm.

- All mechanical, power supply, control, communication, display and other components are arranged in one Machine body, with small volume, high integration and high requirements for design, processing and assembly.

- Friendly interface to ensure the best rheological measurement operation.

- Including the setting of fixture, temperature, test and other parameters required for all DSR tests.

- Try to avoid the influence of operators.

- Time temperature equivalent superposition (TTS) to generate the main curve

ASTM P246, AASHTO T315, JTG E20-2011 T0628

%20TECH_%20SPECS.jpg)

%20SPARE%20PARTS.jpg)