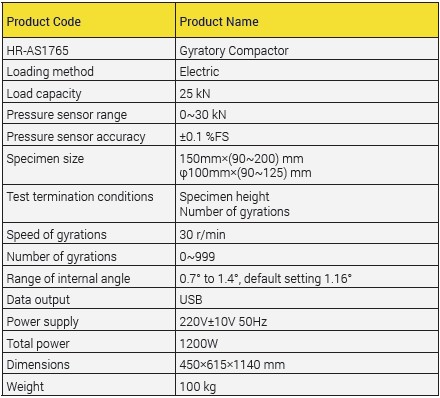

Gyratory Compactor

Gyratory Compactor is used to simulate and reproduce the real compaction conditions in actual road paving operations to determine the compaction characteristics of asphalt and to prepare cylindrical specimens that can be used to test the various properties of asphalt mixtures.

Gyratory Compactor adopts electric loading mode and does not require an external air compressor. During the compaction process, the specimen is simultaneously subjected to the rotary action and the vertical resultant force applied by a mechanical head, thereby simulating and reproducing the on-site compaction conditions during the paving process and ensuring the compaction quality of the specimen. The specimens are particularly suitable for the research, development and verification of new asphalt mixtures such as Superpave and SMA.

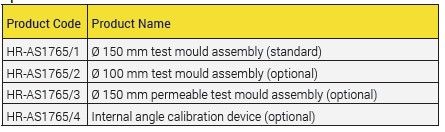

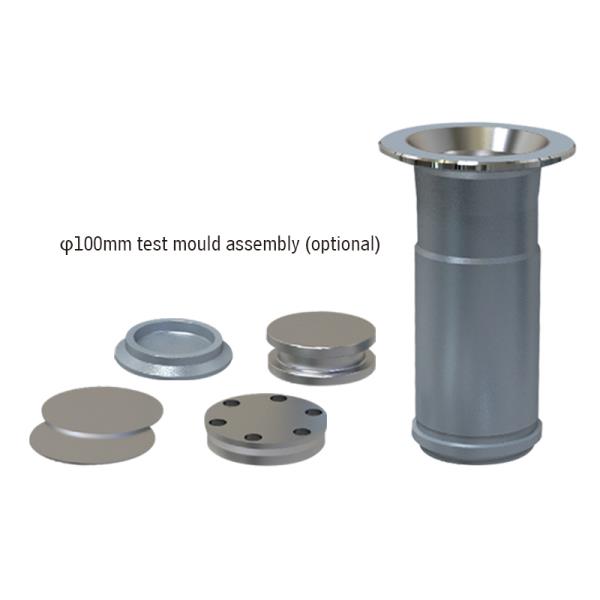

The Gyratory Compactor produces asphalt specimens that best predict long-term pavement performance. This information is not attainable from Marshall hammers or any other laboratory compaction equipment. Automatically measuring the specimen height during consolidation, produces a densification graph that the designer can use to produce the best possible paving mixture. It is equipped with multiple mold sizes and an internal angle calibration device.

The high-rigidity structural steel frame ensures the stability and anti-deformation ability of the equipment while optimizing the weight. It is an ideal choice for mobile laboratories or space-constrained environments.

It adopts servo motor.

A coaxial high-precision pressure sensor (±0.1% FS) is used for control to ensure the accuracy and stability of the vertical compaction force.

Operation can be done on the touch screen, test date can be exported to PC through USB interface.

The internal angle of gyration is continuously adjustable from 0.7 ° to 1.4 ° to meet the requirements of different standards (default setting is 1.16°).

The compaction height and compaction circles can be precisely controlled.

The robust design, precise control and high-quality components ensure the high reliability and repeatability of the equipment in long-term continuous operation and large-scale sample testing.

The high-performance electric actuator only requires a standard single-phase power supply, completely eliminating the need for bulky and noisy external air compressors, significantly reducing operating noise and improving the laboratory environment.

7-inch industrial-grade touch screen provides a clear and sensitive operation interface.

The equipment records complete data and supports USB export for subsequent analysis.

During the compaction process, relevant curves such as "pressure-gyrations" and "height- gyrations" are displayed in real time to facilitate instant monitoring and process analysis.

The transparent glass door makes it easy to observe the compaction process while ensuring safe operation. It can be slid to facilitate the quick loading and unloading of the test mould.

The integrated demoulding device can significantly simplify the sample demoulding process and improve efficiency (optional).

Gyratory Compactor adopts electric loading mode and does not require an external air compressor. During the compaction process, the specimen is simultaneously subjected to the rotary action and the vertical resultant force applied by a mechanical head, thereby simulating and reproducing the on-site compaction conditions during the paving process and ensuring the compaction quality of the specimen. The specimens are particularly suitable for the research, development and verification of new asphalt mixtures such as Superpave and SMA.

The Gyratory Compactor produces asphalt specimens that best predict long-term pavement performance. This information is not attainable from Marshall hammers or any other laboratory compaction equipment. Automatically measuring the specimen height during consolidation, produces a densification graph that the designer can use to produce the best possible paving mixture. It is equipped with multiple mold sizes and an internal angle calibration device.

The high-rigidity structural steel frame ensures the stability and anti-deformation ability of the equipment while optimizing the weight. It is an ideal choice for mobile laboratories or space-constrained environments.

It adopts servo motor.

A coaxial high-precision pressure sensor (±0.1% FS) is used for control to ensure the accuracy and stability of the vertical compaction force.

Operation can be done on the touch screen, test date can be exported to PC through USB interface.

The internal angle of gyration is continuously adjustable from 0.7 ° to 1.4 ° to meet the requirements of different standards (default setting is 1.16°).

The compaction height and compaction circles can be precisely controlled.

The robust design, precise control and high-quality components ensure the high reliability and repeatability of the equipment in long-term continuous operation and large-scale sample testing.

The high-performance electric actuator only requires a standard single-phase power supply, completely eliminating the need for bulky and noisy external air compressors, significantly reducing operating noise and improving the laboratory environment.

7-inch industrial-grade touch screen provides a clear and sensitive operation interface.

The equipment records complete data and supports USB export for subsequent analysis.

During the compaction process, relevant curves such as "pressure-gyrations" and "height- gyrations" are displayed in real time to facilitate instant monitoring and process analysis.

The transparent glass door makes it easy to observe the compaction process while ensuring safe operation. It can be slid to facilitate the quick loading and unloading of the test mould.

The integrated demoulding device can significantly simplify the sample demoulding process and improve efficiency (optional).

AASHTO T312, EN 12697-31, ASTM D6925